Benefits:

- For universal use

- Largest selection of diameters grit sizes and hole patterns

Make an Informed Choice

Description

Extended service life

The exceptionally long service life is the result of Klingspor's Advanced Coating Technology (ACT) and the excellent grit adhesion ACT provides.

Custom hole patterns

Our highly advanced manufacturing technology allows us to produce custom hole patterns made exactly to the customer's specifications.

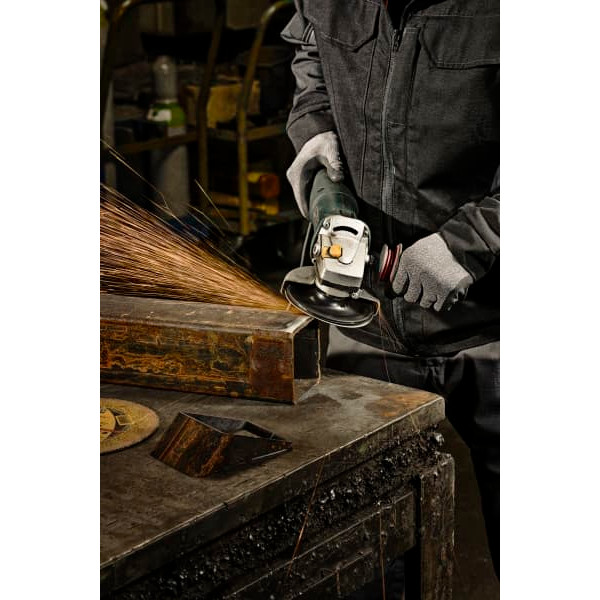

High removal rate

Klingspor fibre discs deliver superior stock removal as their combination of backing, bond and grit is perfectly adapted to the material under processing.

Proven safety

Klingspor fibre discs have been tested according to the guidelines of the oSa directives and are guaranteed to comply with European safety standard EN 12413.

Grit Size

The grit size indicates the abrasive grade on the abrasive side of the paper. A higher grit number indicates a smaller abrasive grain and a finer abrasive product. A “P” in front of the grit size indicates that the product is graded in accordance with the European FEPA standard (www.fepa-abrasives.org).

Indication of use

The terms coarse, medium and fine are often used in conjunction with grit size of abrasive grains. What grits sizes are located within the individual terms?

| 12,16,20 | super coarse | For extra deep and coarse cutting, e.g. floor sanding. |

| 24,30,36 | extra coarse | For coarse cutting. |

| 40,50,60 | coarse | For cutting and sanding uneven surfaces. |

| 80,100 | medium | For sanding marks and uneveness. |

| 120,150,180 | fine | For fine-sanding, and use between and after final surface treatment. |

| 220,240,280,320 | extra fine | For final sanding where there is a particular requirement for a smooth surface. |

| 400,500,600 | super fine | For final sanding where there is a particular requirement for an extra smooth surface. |

| 800, 1200 and finer | ultra fine | For final sanding where there is a particular requirement for and extremely smooth surface. |

Grit size tips

Grit sizes above 240 are defined as extra fine and used mostly on special hard, fine surfaces that require special considerations taken to the surface.

Hard woods are harder to grind than soft. Go up a grit size to avoid scratches you would have to spend extra time to sand away again.

Look for products with a P in front of the grit size. These have a uniform size of grains in its scale related to the FEPA P strandard. This ensures a smooth sanding.

Choose quality products - so you avoid irregularities in the paper that can damage the substrate.

How closely a product is coated - i.e. how many sand grains there are per m2 varies. Typically 50 to 75% of the surface is covered with grain. The coarse grit sizes are usually scattered more open than the finer. A densely littered product immediately gives a good performance at startup. A more open coat can give a better effect over time. This is because dust tends to adhere to the surface and this happens a lot faster with products that have a dense coat.

Hole patterns for fibre discs

|

10 = round hole |

|

|

30 = star shaped hole |

|

|

Additional special cutting shapes are available on request. Please ask us! |

|

The right backing pad

|

Product |

ST 358 | ST 358 A |

|---|---|---|

|

Backing pad form |

Medium hard, flat |

Hard, ribbed |

|

Benefit |

Even grinding finish, good adaptation to the workpiece |

High material removal rates, high stability; Additional benefit of our ribbed backing pad: |

|

Application |

Finish grinding (grit 50 and finer), edge rounding, contour |

Rough grinding (up to grit 40 and coarser), chamfering, |

The hard ribbed backing pad ST 358 A supports the selfsharpening

effect on fibre discs with zirconia alumina

(CS 565, CS 570) and ceramic grit (FS 964,

FS 966), yielding a higher stock removal rate and

longer service life.